I also gave an overview of how to calculate the costs. In this article, I am going to give you the complete breakdown so that you can see how I overcome this objection – so forgive me, this article is a bit longer than usual.

Note: I have used (very) conservative calculations – for both the task base costs and for the time it takes to complete them.

Typical Small and Medium Sized Business (SMB)

I will assume that your client has a helpdesk and purchasing resources to help manage the supplies ordering workflow. Even a very small client who may not have a dedicated helpdesk or purchasing resource will at least have someone performing those functions.

We will join our imaginary user after they have gone through the preliminary checks (which would be managed and potentially avoided in a proactive environment) only to find that their lack of supplies requires them to call their helpdesk.

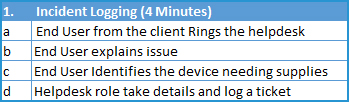

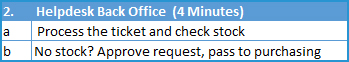

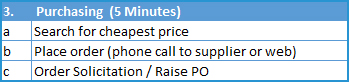

Calculating the time taken to handle one printer incident

*The first task of the process occupies both the end user and the client’s helpdesk staff. This means that an effective total of 8 minutes is used.

- Task 1(4+4) + Tasks 2-4 (4+5+5) = Total of 22 minutes of client’s time taken up performing this process

Calculating the salary costs to handle one printer incident

- Notes:

- I assumed an exchange rate of £1 = $1.42 and I’ve used the following format to show both calculations £1 ($1.42).

- I used this average salary calculator http://www.reed.co.uk/average-salary to get an average annual salary of £36,820 ($52,284).

Calculations

Step One – Calculate the Salary Uplift

Uplift salary by Cost of Employment – Pension, Desk, Phone, PC etc. in this example we have used an industry average of 30%.

30% of £36,820 ($52,284) = £11,046 ($15,685)

Step Two – Calculate the Shrinkage

Shrinkage takes into account the holidays / vacations, sickness, breaks, and is an uplift of a conservative 10 % of the salary

- 10% = £3,682 ($5,228)

Shrinkage example – 100% salary / 52 weeks, But you only work 48 as an example, 10% is 6 weeks out of 52 weeks.

Step Three – Calculate the annual cost

With cost of employment and shrinkage, the annual cost of that employee then becomes:

- Annual Salary + Uplift + Shrinkage = £51,548 ($73,197)

Step Four – Calculate the cost per minute

Take the annual cost and then divide by 52 weeks, by 5 working days, by 8 hours by 60 minutes you get a cost of £0.41 ($.59) per minute.

Putting it all together

If you then multiply the 22 minutes by the £0.41 ($.59) you get £9.02 ($12.98) as the cost of performing the supplies ordering workflow.

The more devices the client has, the more volume they produce, the higher the page coverage and the use of colour will hasten the intervals between the cost triggers.

The HDI Support Center Practices & Salary Report supports this. They estimate that the average help desk call costs £9.86 ($14).

Remember, this is just the IT side of the costs, which shows that my calculation really is very conservative.

IDC estimates that 51 percent of all IT Helpdesk calls are print-related That is a lot of time spent dealing with supplies issues that the IT helpdesk does not have the time or inclination to deal with.

Duplicate calls and false alerts add additional costs

In some situations, multiple users could report the same issue for the same device. There may also be many other types of “false alerts” encountered by the client. These would use a proportion of this four-step incident process, incurring additional soft cost implications.

I have not accounted for any duplicate calls or false alerts in this exercise, but it is worth noting when discussing with your clients.

Calculating the costs for small businesses / solopreneur

For smaller clients or those where an individual user manages their entire supplies process? For this group it can be even worse. These knowledge workers are typically ill-equipped to order consumables effectively.

They waste their valuable working time logging the call to the helpdesk or trawling websites looking for a good deal. You can see that, for them, the supplies workflow could take much longer. They are also more likely to order small quantities, making the shipping costs per item expensive.

Not to mention that, with smaller quantities, the chances of lost delivery compounds the issue further.

The efficiency principle

Now that you have an appreciation for the cost of managing a supplies workflow the question is, can you radically reduce this burden?

Our approach is to introduce process efficiencies before the supplies workflow becomes a helpdesk issue. We do this by enabling our channel partners to provide proactive supplies automation. Easily said, but difficult to do effectively whilst maintaining the client’s peace of mind.

By providing robust supplies automation agents on the network, the client is less likely to contact the helpdesk because, in the majority of cases, the supplies (toner and CRUs) arrive just before full depletion.

It is also important to mention that you need a service contract that covers the proactive management of the different supplies types, including toner and other consumables like fusers and waste toner boxes.

Multiple manufacturers are a common occurrence

Moreover, you need to ensure that this proactive service is available for the many brands that your client has in their fleet and not a ‘cherry-picked’ subset of easy to manage models and vendors. If you do not provide a complete service, the client still has to manage the remaining devices.

A true holistic service, in turn, reduces the burden on the helpdesk and purchasing departments. In addition, the client can also get valuable insights from the extensive reporting tools.

If your client insists on continuing with a ‘toner-out’ approach then Xerox Enhanced Managed Supplies Service (eMSS) will enable them to save these soft costs and allow you to capture the supplies revenue, and help the client make a significant saving in their hard supplies cost.

One last thing… In this calculation, I have not taken into account the cost of actually managing the supplies inventory, supplies obsolescence or the actual cost of supplies. On top of that, I’m going to leave asset management for another day…

Take every opportunity to uncover these hidden costs

Of course, by completing a full print assessment using the tools provided by NewField IT, you could go even deeper and provide irrefutable documented evidence of how your client’s print infrastructure and document workflow effects their business viability.

Until then, this relatively simple cost calculation should help you get their attention. I hope that from now on, you will never pass on the opportunity to uncover the hidden costs of self-managed supplies management.

Learn more about Xerox Partner Print Services

If you’d like to learn more about adding managed print services to your portfolio you can find out about becoming accredited to sell Xerox Partner Print Services on the Xerox Global Partner Portal.

Subscribe to the Channel Partner Connection and receive email updates when we publish a new article.

Great Article, now I understand better an area that always confused me, thanks

Thanks John – I appreciate you commenting

Great article .

This is a very insightful articles and I learnt a lot, I now see some of the world of work flow from this perspective. Looking forward to learning more.

Hi John, thanks for leaving a comment. If you have any specific topics you’d like us to cover in future please let us know.